Now Coffee

URAGA RARO | ETHIOPIA

URAGA RARO | ETHIOPIA

Regular price

R 200.00 ZAR

Regular price

Sale price

R 200.00 ZAR

Unit price

per

Tax included.

Shipping calculated at checkout.

Couldn't load pickup availability

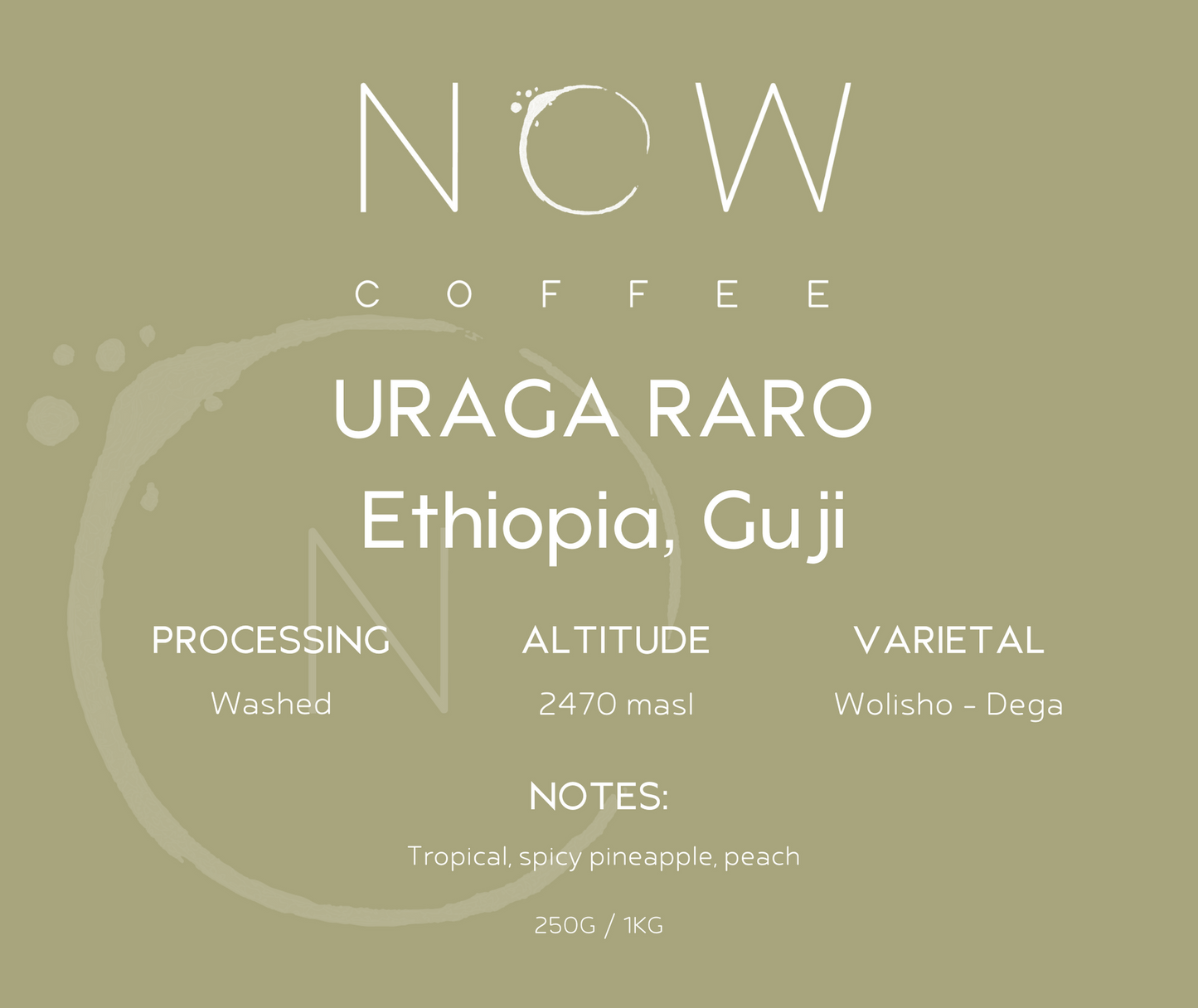

URAGA RARO

ETHIOPIA

GUJI

PROCESSING: WASHED

VARIETAL: WOLISHO - DEGA

NOTES: TROPICAL, SPICY PINEAPPLE, PEACH

ALTITUDE: 2470 MASL

COFFEE INFO:

Raro Coffee Processing Station is a washing station located in Guji which buys cherries from around 1500 neighbouring farmers. Uraga Raro is owned by SNAP COFFEE exporters. The farms that supply cherries to this washing station have high yields as the soil is quite fertile and farming methods are to a very high standard. We only buy washed coffees from this washing station even though they also prepare naturals.

The company’s supply policy rests on three main pillars:

Care information

Care information

Please Store in a cool dry place