Now Coffee

EL PLACER WINE YEAST | DOUBLE FERMENTATION | EXCLUSIVE RELEASE

EL PLACER WINE YEAST | DOUBLE FERMENTATION | EXCLUSIVE RELEASE

Couldn't load pickup availability

EL PLACER

COLOMBIA

CATURRA WINE YEAST

PROCESSING: CARBONIC MACERATION HONEY YEAST

VARIETAL: CATURRA

NOTES: MIND BLOWING

ALTITUDE: 1744MASL

NOTE: NO ALCOHOL WAS USED IN FERMENTATION

Farm Info

This very special lot of Caturra Wine Yeast is produced on Finca El Placer, by Sebastian Ramirez, a 4TH generation coffee producer who has been running his family estate for over a decade.

El Placer means ” The Pleasure”, and the farm is located in the heart of El Eje Cafetero (the coffee zone) in Calarca, Quindio at 1.744MASL. At El Placer, avoiding herbicides and cutting weeds every two months is part of a sustainable approach to farming. They prioritise soil health, which results in healthy plants and contributes to great flavour profiles too. Sebastian has access to a well-equipped microbiology laboratory, crucial for the El Placer team in developing innovative and exotic coffees.

Sebastian uses natural, washed, and honey processes, and all the varieties undergo carbonic maceration. Most of the coffee is processed naturally or via honey, to minimize water consumption. In his quest to maximise the flavour potential of every variety, Sebastian is taking a step forward by adding the “musto” from cherries to the coffee during fermentation.

Caturra Wine Yeast Process

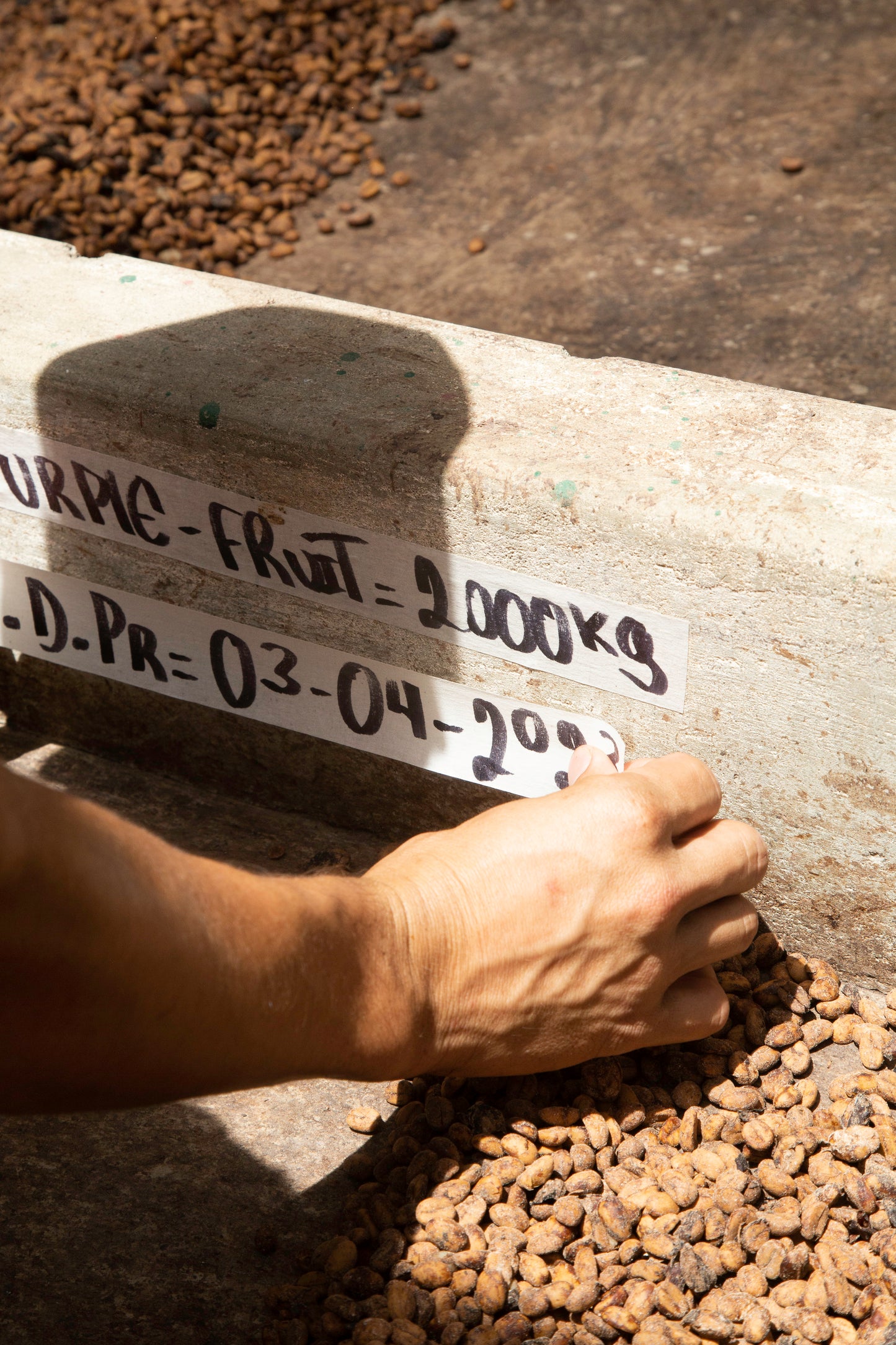

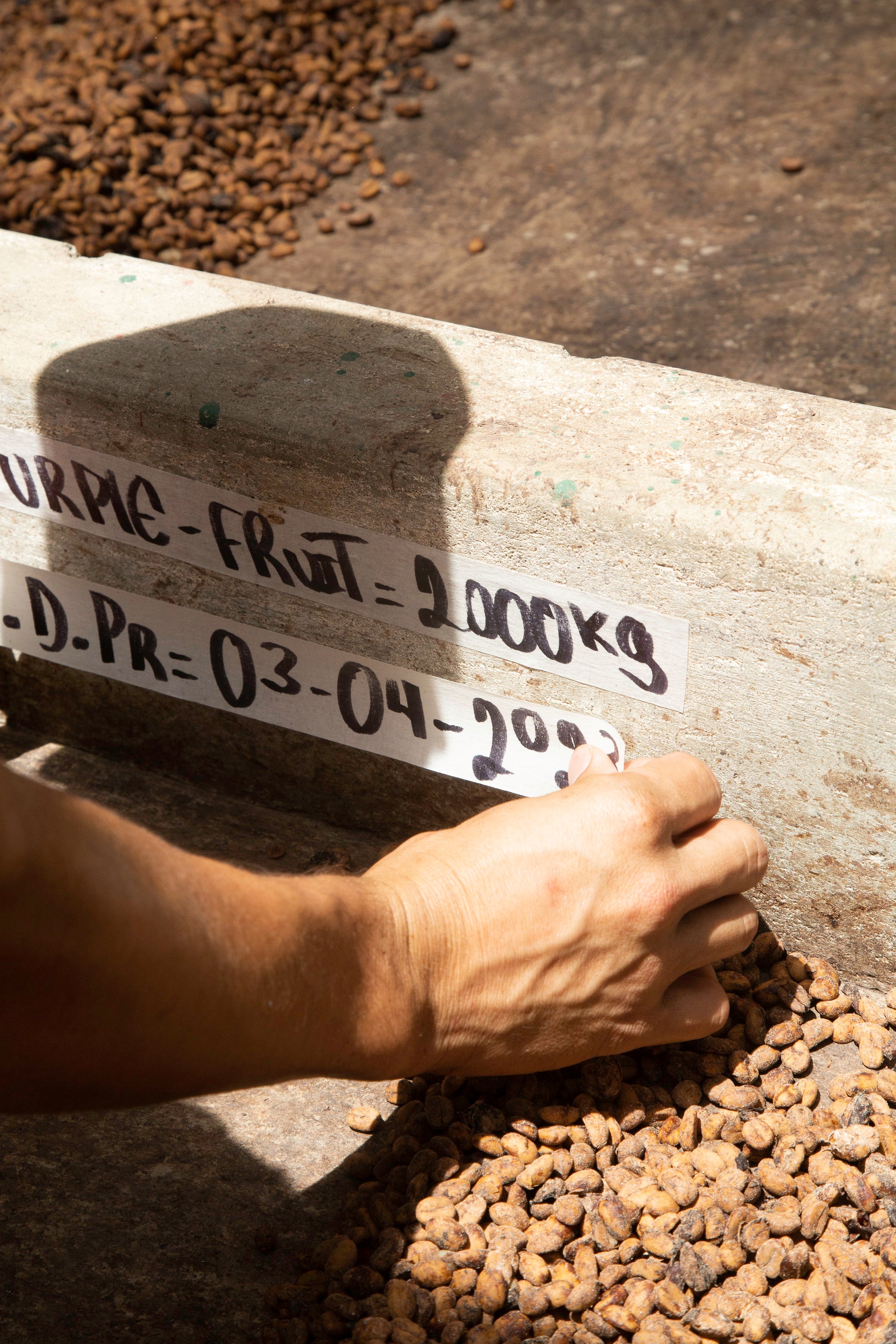

The first step of processing is the three-step hand selection:

- 95% of ripe and 5% of semi-ripe cherries are selected, all by hand.

- The selection continues with submerging the cherries in water tanks and removing the floaters from the surface.

- Lastly, the cherries without any visible defects are sorted to guarantee only the best quality ones to undertake the fermentation processes.

For the Caturra Wine Yeast process, coffee is fermented twice anaerobically. The first step is to seal the coffee cherries inside 200L plastic cans for 180hrs at a constant temperature of 18 ° C, adding wine yeasts.

The cherries undergo pulping and another anaerobic fermentation for 72 hours in tanks with CO2 injection (a process called carbonic maceration) including the addition of dried fruits and fructose.

Throughout the fermentation, the PH levels and temperature are carefully monitored. Lastly, the coffee is dried under canopies for up to 5 days at 40 degrees. This is a slow and controlled drying process.

Care information

Care information

Please Store in a cool dry place